Metal bending is a forming process in the mechanical industry.

Metal bending definition

Metal bending is the process of shaping metal through plastic deformation to create parts with a specific angle, such as rings, letters U, I, L, etc.

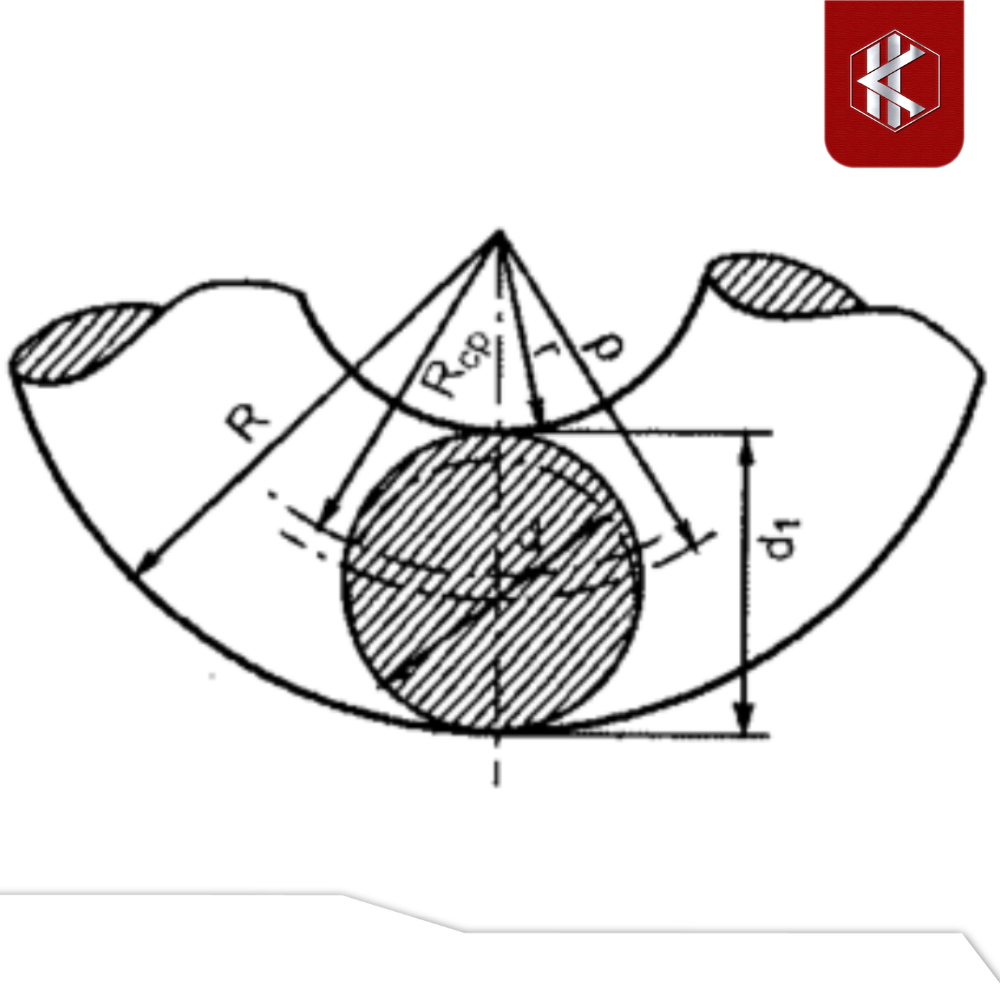

During the bending process, the metal layers inside the bend angle (on the punch side) experience compression and contraction in the longitudinal direction, and are pulled in the transverse direction.

On the other hand, the metal layers on the outside (side of the die) undergo tensile elongation in the longitudinal direction and compression in the transverse direction.

When bending narrow strip workpieces, the cross-section will change from rectangular to trapezoidal. For large diameter round bars, the cross-section typically remains unchanged. However, when bending a round bar with a small bending radius, the workpiece cross-section will become distorted and oval in shape.

- When bending narrow strip bars, the cross-section will change from rectangular to trapezoidal.

- For large diameter round bars, the cross-section typically remains unchanged.

- When bending a round bar with a small bending radius, the workpiece cross-section will become distorted and oval in shape.

A round bar’s cross-section will become distorted when its bending radius is less than 1.5 times its diameter

- Specialized bending machines are commonly used for bending other rolled metal shapes such as U, I, L.

Metal bending Applications

- Hydraulic Connections

- Hydraulic Systems (such as oil pipes for excavators, etc.)

- Motorcycle and Scooter Accessories

- Office, Shop, Hospital Furniture, etc.

- Gym Equipment

- Door Handles

- Food Industry Equipment

- …

Metal Bending Methods

- Metal Sheet Stamping

- Metal Sheet Bending

Pipe Bending Methods

- There are several methods for bending pipes, including: Bending on jigs, Bending between two rollers, Bending on specialized bending machines, and Bending on stamping dies.

- The process of bending a pipe into a ring involves three steps: Bending one end to the desired radius → bending the second end → winding the entire loop.

- The minimum bending radius for pipes depends on the material type, pipe wall thickness, and bending method.

Types of materials that can be bent

- Hot-rolled steel

- Carbon steel plate

- Alloy steel

- Stainless steel in various shapes and sizes such as: Sheet, round plate, seamless pipe, welded pipe, etc.

- Standard seamless pipe

- Shaped steel (U, I, V, H)

- Sheet aluminum

- Iron

- Alloy copper

- Stainless steel

- Welded steel pipe

- Black square, rectangle box steel, etc.

Contact Ha Ky Anh company for more detailed advice on metal bending and finished products!