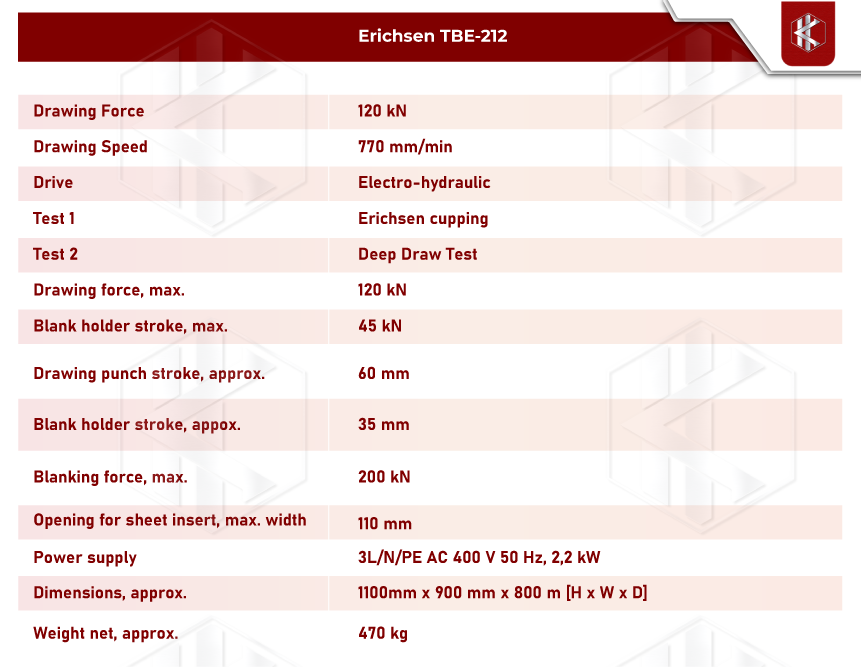

Fully automatic cupping and deep-drawing cup test machine Model 212 for testing the ductility of coated, ferrous and non-ferrous metals (e.g. stamping paints, lacquered, plastic coated or electroplated materials). The testing machine is provided with an electro-hydraulic drive and a maximum drawing force of 120 kN. The machine is operated via a resistive touch panel. The operation is simplified by the user-friendly menu navigation. Main and emergency Off switches are located next to the touch panel. The setting of sheet holding force and forming speed is carried out by ergonomically placed control buttons on the front of the housing.

Application

When manufacturing deep-drawn products the ingoing material is deformed in all three coordinating planes.

Thereby the surface coating should not become defect to avoid subsequent corrosion. For the standard controls and proofs required for the purposes of quality assurance Model 212 is particularly suitable to conduct cupping and deep-drawing cup tests within the sheet metal thickness range of 0.1 mm to 3.0 mm. To intensify the tests by further special investigations, it is possible to carry out without any problem a redraw (a second deep-drawing operation conducted on the standard cup using a smaller drawing die and drawing punch). Furthermore, the Bead Test Instrument, Model 227, can be used to form a bead into the cylindrical wall of a standard cup until a mechanic destruction of the coating is achieved. This is another possibility to intensify the test. The above mentioned sheet thickness range of 0.1 mm to 3.0 mm is based on material with a tensile strength of 400 N/mm². In case of a higher/lower tensile strength the values mentioned concerning the maximum sheet thickness that can be drawn, are to be reduced/increased.

Purpose

The following reasons are important for using the Cupping and Deep-drawing Cup Test Machine, Model 212, for quality assurance, research and development:

- Lowering of the reject rate by concerted monitoring of the coating quality during production or in the process

department. - Immediate sorting out of lower quality arriving at the goods inwards department by means of the Erichsen

cupping test or the deep-drawing cup test. Without special test preparations it is possible to establish, if the material supplied corresponds to the prescribed properties. - The sturdy construction and hydraulic operation ensure a wear-resistant functioning of the machine so that high accuracy of the test results at low maintenance and working expenses is guaranteed.

Norms

- DIN EN ISO 1520

- DIN EN 13523-6