Introdution

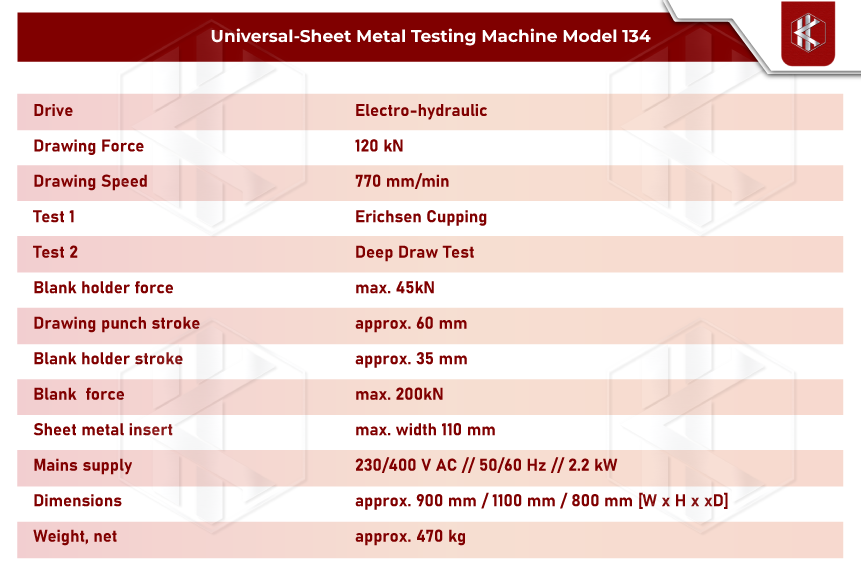

The Sheet Metal Testing Machine, Model 134, with electro-hydraulic drive, max. drawing force 120 kN and adjustment for pre-setting the blank holder pressure max. 45 kN, blanking head (max. blanking force of 200 kN), automatic test sequence and facility for automatic stop at specimen failure. The machine is operated via a resistive touch panel(automatic menu navigation).

Purpose and Application

This Sheet Metal Testing Machine is not only ideal for the effortless, quick and accurately all important and known-deep drawing tests for ferrous and non-ferrous metals, it is also designed for a large number of additional technological investigations. In addition, the Olsen Test as used in the USA can be performed, if appropriate tools are set up.

There are important reasons for using Sheet Metal Testing Machine, Model 134, for quality assurance and research:

- Lowering of manufacturing costs by making spot checks on the drawing quality of cold rolled sheet during production or in the process department.

- Sorting out of material of lower quality arriving at the Goods Inwards Department. Without special test preparations it is immediately possible to establish if the material supplied has the prescribed drawing quality.

- Determining the most appropriate sheet thickness for a particular drawn workpiece to optimise the ratio of price to suitability for the manufacturing process.

Norms

- ISO 8490

- EN 14-58

- EN 14-67

- EN ISO 20482

- JIS Z-2247

- DIN EN 1669

- ISO 11 531

- JIS Z 2249

- GB/T 15825